Minneapolis Gourmet Mushroom Cultivator Repurposes WFTH Sawdust

April showers bring May flowers—and mushrooms!

When we reclaim a tree taken down in our urban environment, we introduce a multi-generational stop-over that wouldn’t otherwise exist. We make use of the valuable resource that is our urban forest by giving these trees new life and appeal as architectural elements, furnishings, and lumber. Rather than speeding along to decomposition as mulch, we’re storing the carbon from these trees for future generations. For those of us concerning ourselves with sustainability, zero-waste industry, and cradle-to-cradle systems, you’ll be happy to hear that we’ve even interrupted the life-cycle of our by-product, sawdust.

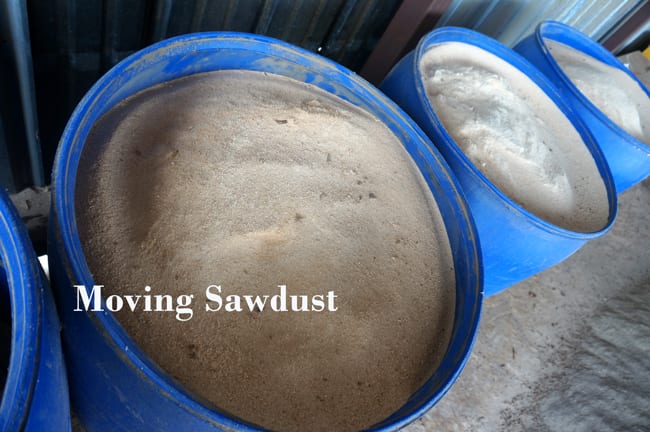

Rather than going directly to compost, Mississippi Mushrooms puts our sawdust into service as a substrate for growing wood-eating fungi like King Oyster and Lion’s Mane. We followed the journey of our sawdust to tell you the tale.

Mississippi Mushrooms is located in North Minneapolis, at the Upper Harbor Terminal, in the Barge Terminal building. The port has been largely unused since the City of Minneapolis pulled out of the port business in 2014. Ian Silver-Ramp, the proprietor of Mississippi Mushrooms, moved into a small corner area of the 110,000 square foot Barge Terminal Building last year. There he built customized rooms to maintain variable conditions for lab work, incubation, and growing.

Here, our sawdust, like other local by-products such as mustard chaff, spent brewer’s grain, and coffee chaff, is put into bags with water and gypsum.

These bags are loaded onto a cart and then into a small sterilizing retort that kills any mold or bacteria in the substrate. The sterilized substrate cools down in the first half of the clean lab. In the second half of the lab, tempeh-like inoculating spawn is added to the substrate and shaken well. (Holes are poked in the bags only after the mushrooms have incubated.) Four more custom-built rooms are digitally controlled to maintain the temperature, humidity, and CO2 concentration, among other variables, for the incubation and growing conditions that bring the mushrooms to fruition.

With 4 of these rooms, one can be rotated out of production periodically to dry. After 4-6 weeks, the mushrooms are ready to be harvested; a daily event. The bags continue to fruit but with diminishing returns—with the exception of King Oysters which fruit only once.

Only then, once exhausted, does the substrate in these bags finally become enriched garden compost!

You can find Mississippi Mushrooms in our local environment by visiting commercial establishments such as The Bachelor Farmer, Create Catering, Restaurant Alma, Eastside Food Coop, Wedge Community Coop, and the Seward Coop. Visit Mississippi Mushroom’s website or Facebook page to become a commercial client, or to purchase wonderfully rich compost for your garden.

my blog

July 22, 2017 at 1:16 amHi there! Someone in my Facebook group shared this website with us so I came to check it out. I’m definitely enjoying the information. I’m bookmarking and will be tweeting this to my followers! Superb blog and amazing design.